“Marine Industry of Russia”

«President-Hotel»

Department of affairs of the President of the Russian Federation

Moscow, 24, B.Yakimanka Str

24-25 May 2017

May 07, 2015

Greetings from the Ministry of Industry and Trade of the Russian Federation

January 28, 2015

The Forum organizers received the greeting from Gutenev V.V., the First Deputy Chairman of the Russian Engineering Union.

January 15, 2015

The Government of the Russian Federation addressed a welcome letter to the V International Forum Marine Industry of Russia.

Hulls and Their Structural Components – Brief Overview

A hull is a primary structural element ensuring buoyancy as well as total and local durability of a vessel. In general, the hull consists of a shell and framework. The outer plating (bottom and side plating and decking) ensures tightness of the hull to water while inner plating divides it in compartments thus guaranteeing survivability in case of hull damage. The framework is also called a framing.

Since the hull operates between two environments (water and air) and is exposed to loads with constantly and randomly changing values and vectors, the framing composes the group of structures which durability is the most difficult parameter to estimate. Members of ship’s hull undergo several types of deformation.

The rigid member of the framing designated for longitudinal and lateral loads is called a frame.

The members of the framing are:

- Longitudinal –

- stringers,

- carlings,

- keel,

- Latittudinal –

- transverse frames,

- beams,

- floorings,

- Vertical –

- pillars,

- bulkheads.

In the fore and stern, the framing is fixed at the stem and the stern-frame which close the hull.

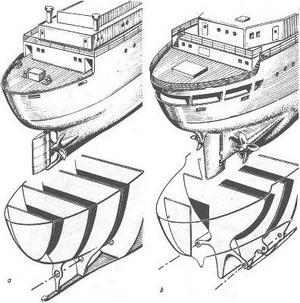

The frames of the framing run in parallel with the sides of the support contour. The frames prevailing in number are called the frames of principal direction and those perpendicular to them are cross frames. Depending on location of the frames of principal direction, there are transverse, longitudinal and combined framings.

In the transverse framing, the frames of principal direction are beams (in deck covering), ribs (in board covering), floorings (in bottom covering). Such system is most advantageous at icebreakers and ice ships, since it ensures high resistivity of the hull in conditions of transverse contraction with ice.

In the longitudinal framing, amidships the frames of principal direction run along the ship while ship’s extremities are made in accordance with the transverse framing. In such case bottom, board and deck longitudinal enforcement ribs are the frames of principal direction of amidships bottom, board and deck coverings while floorings, transverse frames and beams are cross frames. Such framing is most advantageous at long ships when the hull is exposed to bend loads.

At last in the combined framing, deck and bottom covering amidships are made according to the longitudinal framing while board covering amidships and all covering at the extremities – according to the transverse framing. It is applied to large-capacity dry bulkers and low-slung tankers.

Features of Ship Hull Form

The form of the hull is defined by ship’s type and nomination. Estimated speed, transverse stability, necessary hold volume, cargo tonnage (deadweight), and number of decks also affect. Estimated operation conditions (dimensions of bridges and locks which the vessel will pass through, clearance limitations owing to natural conditions as well as need for special tasks, i.e. tug or icebreaking works) count, too.

The form of underwater hull up to design waterline is, as a rule, compromise. It depends on ratio of ship’s principal dimensions and fullness ratio. However, it is necessary to seek after balance of minimum power of main engines and heavy deadweight when designing, for example, cargo vessels. Small, i.e. advantageous, fullness ratios are used only for fast cargo vessels (for example, refrigerator ships).

The form of underwater hull up to design waterline is, as a rule, compromise. It depends on ratio of ship’s principal dimensions and fullness ratio. However, it is necessary to seek after balance of minimum power of main engines and heavy deadweight when designing, for example, cargo vessels. Small, i.e. advantageous, fullness ratios are used only for fast cargo vessels (for example, refrigerator ships).

The form of the ship is determined taking into account estimated operation conditions and traditional form for such type of a ship; the form of extremities depends on aesthetics and ship’s resistance. At that, special purpose vessels are equipped with stems of certain types (for example, icebreakers). The icebreaker serves to break ice by its own weight. For the purpose the knuckle of stem waterline should be convex, and the angle of entrance should be not too big, so that ice floes don’t draw back. Double-propeller ships have such hull contours that the incoming flow hit the propeller against direction of rotation.

Basing expertise and mathematical models, several types of line forms were designed with optimum deadweight-speed-seaworthiness-stability ratios. But large vessels and new ship series need to perform additional model tests.

Materials for Ship Hulls

Today, nearly all hulls are made of hull steel which plates are joined with welding or, more rare, with rivets.

Carbon or low-alloyed steel (plates, sections, etc) certified in accordance with the requirements of the Register of the Russian Federation or another classification association can be used as hull steel. The standards for shipbuilding steel are specified in the Rules of classification and construction of sea-vessels of the Register of the Russian Federation (part XIII, Materials) as well as in GOST 5521-86 “Rolled Steel for the Shipbuilding Industry”.

The Register of the Russian Federation stipulates application of standard-strength shipbuilding steel of categories A, B, D, E (yield point 235 MPa), high-strength steel of categories A32, D32, E32 (yield point 315 MPa), A36, D36, E36 (yield point 355 MPa), A40, D40, E40 (yield point 390 MPa), and high-strength steel for manufacture of hull constructions of sea-vessels.

Aluminum alloys, plastics and even timber can be used in construction of small vessels.

© Marine Industry of Russia, 2009-2010. All rights reserved.

By: “Ideological buiseness-projects”

Design by Valentina Ivanova.